Upgrade Your Mechanical Systems with Precision-made Bronze Bushing

Efficiently Decrease Rubbing With High-Quality Bearing Bushings

One efficient method to achieve this is with the usage of premium bearing bushings. In this discussion, we will explore the importance of birthing bushings, the aspects that impact rubbing in equipment, the benefits of using high-grade bushings, and offer sensible tips for picking and installing them. Allow us begin on this journey to uncover how premium bearing bushings can effectively reduce rubbing and improve the efficiency of machinery.

Relevance of Bearing Bushings

Bearing bushings play a vital function in making sure the reliable and smooth operation of different mechanical systems. These tiny elements are made to minimize rubbing and give support for revolving or sliding shafts. By serving as a barrier between relocating components, bearing bushings aid to lessen wear and tear, prolong the life expectancy of machinery, and enhance total performance.

One of the vital functions of birthing bushings is to lower rubbing. Birthing bushings are made from materials with low coefficients of rubbing, such as bronze or self-lubricating polymers, which assist to lessen this friction.

In addition to minimizing friction, bearing bushings also give support and security to turning or moving shafts. They assist to keep proper alignment and avoid excessive movement or vibration, making certain that the mechanical system runs efficiently and accurately. Without the support of birthing bushings, the shafts might be susceptible to misalignment, bring about increased rubbing, wear, and possible damages to the whole system.

Variables Influencing Rubbing in Machinery

As the smooth procedure and durability of machinery depend heavily on reducing rubbing, it is important to understand the numerous aspects that add to friction in equipment. There are a number of factors that affect rubbing in machinery.

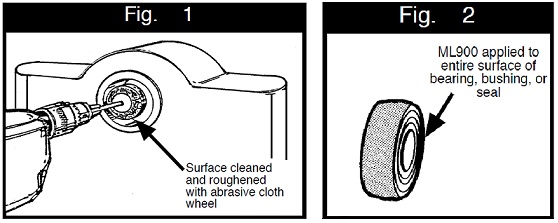

The initial aspect is surface roughness. When the surface areas of 2 components are harsh, the contact location boosts, causing greater rubbing. Polishing or lubricating the surface areas can reduce friction by raveling the roughness.

The second aspect is the type and quality of lubrication. Proper lubrication creates a thin movie in between the relocating surface areas, lowering direct get in touch with and reducing rubbing. The viscosity and temperature level of the lubricant likewise play a significant function in rubbing reduction.

The third factor is the tons or stress applied to the surfaces. Higher lots increase the surface get in touch with location and the rubbing force. Appropriate load distribution and harmonizing are essential to avoid excessive rubbing.

Furthermore, the rate of the relocating components, the product homes of the parts, and the environmental conditions, such as temperature and humidity, can additionally affect rubbing in machinery.

Advantages of Using High-Quality Bearing Bushings

Using top quality bearing bushings provides many benefits in regards to boosting equipment performance and durability. These benefits make buying top notch bearing bushings a sensible decision for companies operating heavy machinery.

Among the key advantages of making use of top quality bearing bushings is lowered rubbing. Rubbing is a significant aspect that can cause damage on equipment elements, leading to decreased performance and enhanced upkeep prices. Premium bearing bushings are developed to lessen friction, enabling smoother operation and decreasing the threat of damages to machinery parts.

Additionally, top notch bearing bushings contribute to improved efficiency. By reducing friction, these bushings aid to optimize power transfer within the equipment, causing boosted efficiency and decreased energy intake. This not only improves total efficiency but additionally aids to lower functional costs in the future.

Sorts Of High-Quality Bearing Bushings

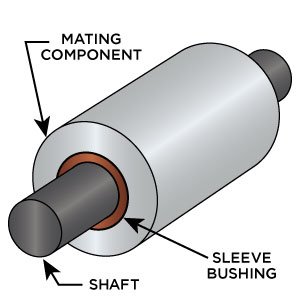

There are numerous unique varieties of top notch bearing bushings readily available on the marketplace. Each type is designed to satisfy certain demands and needs, making certain efficient reduction of friction in numerous applications. One preferred type is the ordinary bearing bushing, likewise called a sleeve bearing or journal bearing. This type of bushing contains a round sleeve made of materials such as bronze, steel, or brass, and it supplies a low-friction interface in between revolving shafts and stationary elements.

One more type is the moving aspect bearing bushing, which is generally used in applications where greater rates and heavier lots are included. This kind of bushing integrates rolling components such as rollers or spheres, which permit smoother and a lot more effective turning.

Self-lubricating bearing bushings are likewise commonly used, especially in applications where maintenance is expensive or difficult. These bushings are made from products such as Nylon, ptfe, or graphite and have integrated lubrication properties, getting rid of the requirement for exterior lubrication.

Tips for Finding and Putting Up Bearing Bushings

One crucial consideration when choosing and setting up high-quality why not try these out bearing bushings is to meticulously evaluate the particular requirements and applications, building on the knowledge of the distinct types stated in the previous subtopic. To start with, it is critical to understand the tons capability and rate needs of the application. This will aid in determining the appropriate material and layout of the bearing bushing to guarantee optimal performance and longevity.

An additional factor to consider is the operating setting. Whether the bushings will certainly be exposed to high temperatures, destructive chemicals, or severe climate condition, it is necessary to choose a material that can stand up to such problems without compromising its performance.

In addition, the installation process plays a substantial function in the effectiveness of the bearing bushings. It is important to make certain proper alignment and fitment to stop any type of unneeded stress or misalignment that can lead to early failure. bronze bushing. Lubrication is additionally crucial find more to lower rubbing and wear in between the bushing and the turning shaft

Lastly, routine assessment and maintenance are required to guarantee the continued performance of the bearing bushings. This includes checking for indicators of wear, monitoring lubrication degrees, and dealing with any problems promptly.

Final Thought

In conclusion, premium bearing bushings play an important function in decreasing rubbing in machinery. It is essential to invest in premium bearing bushings to achieve ideal performance and durability.

In this discussion, we will explore the value of birthing bushings, the aspects that affect friction in machinery, the advantages of utilizing premium bushings, and give useful ideas for picking and installing them. Allow us get started on this trip to discover exactly how top notch bearing bushings can successfully minimize friction and enhance the efficiency of machinery.

Birthing bushings are made from materials with low coefficients of rubbing, such as bronze or self-lubricating polymers, which assist to reduce this rubbing. High-quality bearing bushings are designed to minimize friction, allowing for smoother operation and lowering the risk of damage to equipment components.